Introduction to Epoxy Resin Floors

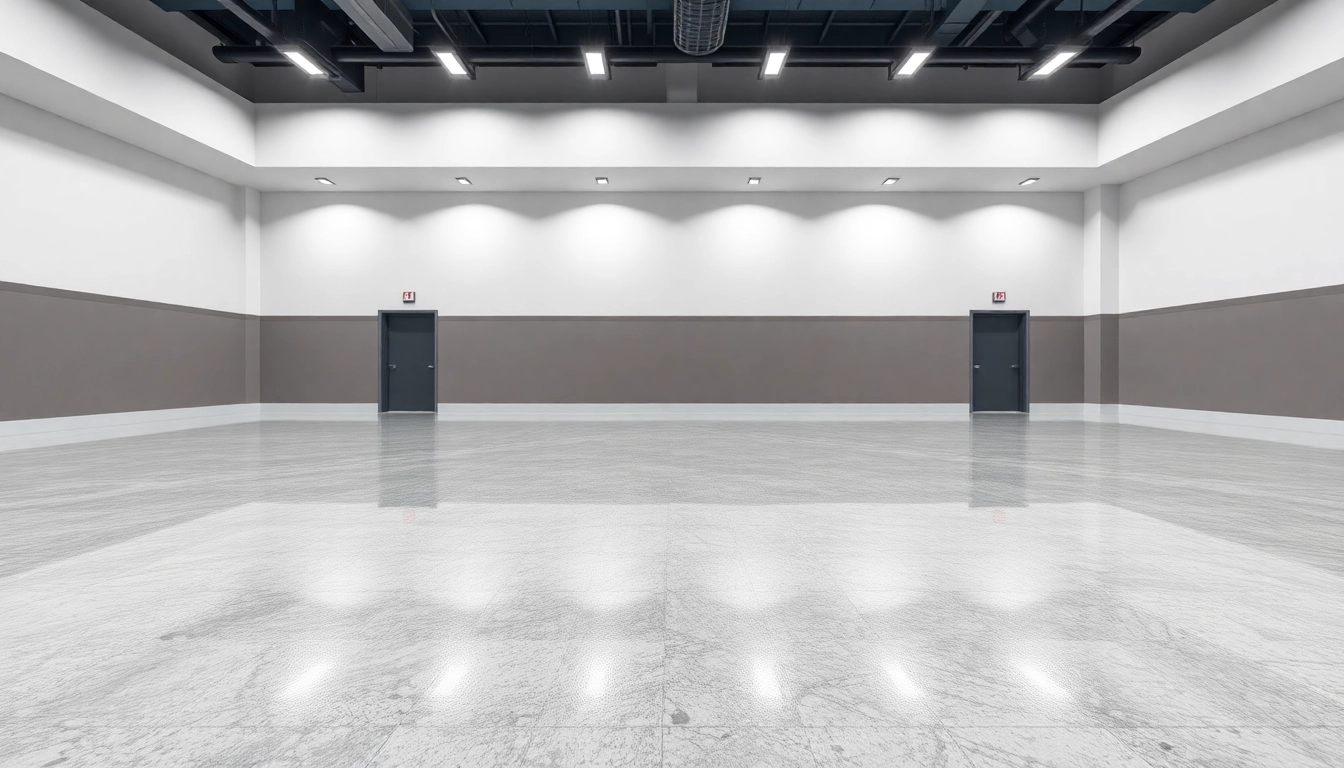

Epoxy resin flooring has revolutionized the way residential, commercial, and industrial spaces approach surface durability and aesthetic appeal. Known for its exceptional strength, seamless finish, and customizable design options, an epoxy resin floor offers a versatile flooring solution that combines functionality with style. Whether you’re renovating a garage, outfitting a warehouse, or creating a high-end commercial space, understanding the intricacies of epoxy flooring is essential for making informed decisions and achieving lasting results.

What Is an Epoxy Resin Floor and Its Benefits

At its core, an epoxy resin floor is a surface coating made from a combination of epoxy resin and a hardening agent, applied directly onto concrete or other substrates. This chemical reaction creates a durable, rigid, and highly adhesive layer that bonds strongly to the substrate, providing a resilient barrier against wear, chemicals, and moisture.

The benefits of epoxy resin floors are extensive:

- Durability: Epoxy floors are resistant to impact, abrasion, and heavy loads, making them ideal for high-traffic areas.

- Ease of Maintenance: Seamless surfaces prevent dirt and bacteria accumulation, simplifying cleaning routines.

- Chemical and Stain Resistance: Properly sealed epoxy resists common spills, oils, and corrosive substances.

- Enhanced Aesthetics: Versatile design options enable customization to match any décor or branding requirements.

- Cost-Effectiveness: Long-term durability translates into lower maintenance and replacement costs over time.

To explore further options and innovative products, visit our website for tailored epoxy flooring solutions.

Common Applications in Residential and Commercial Settings

Epoxy flooring’s adaptability makes it suitable across numerous environments:

- Garages and Workshops: With resistance to oils, chemicals, and impacts, epoxy floors are perfect for car parks, garages, and DIY workshops.

- Industrial Warehouses: Heavy-duty epoxy systems withstand forklift traffic, machinery, and frequent cleaning, ensuring longevity under rigorous conditions.

- Commercial Spaces: Retail stores, showrooms, and restaurants benefit from attractive, seamless surfaces that facilitate hygiene and aesthetics.

- Residential Areas: Basement conversions, kitchens, and even living rooms are being transformed with stylish epoxy finishes, offering durability alongside design flexibility.

Case studies illustrate how businesses and homeowners leverage epoxy flooring to create functional and visually appealing spaces.

Why Choose Epoxy Resin for Your Flooring Project

The decision to opt for epoxy resin floors stems from their unmatched combination of performance and design capabilities:

- Long-Term Investment: Epoxy floors typically last 10-20 years with proper maintenance, providing significant value.

- Customizable Aesthetics: Variety in colors, textures, and finishes allows for tailored interior design concepts that reflect brand identity or personal style.

- Rapid Installation: Compared to other flooring options, epoxy coatings can be applied efficiently, reducing downtime.

- Seamless Surface: Eliminating joints and crevices, epoxy floors promote a safer, cleaner, and more hygienic environment.

Choosing the right epoxy system and professional installer ensures optimal results, longevity, and aesthetic appeal.

Design Options and Customization

Color, Texture, and Finish Variations

Epoxy flooring design is limited only by imagination. From classic solids to complex patterns, options include:

- Solid Colors: Single-tone finishes for a sleek, uniform look.

- Color Flakes and Chips: Adding decorative flakes creates texture and hides imperfections.

- Metallic Effects: Swirling metallic pigments produce a luxurious, high-end appearance.

- Matte, Glossy, or Satin Finishes: Finish options alter the reflection and slip-resistance of the surface.

Texture can be textured for slip resistance or kept smooth for ease of cleaning. Various finishes can be combined to match aesthetic and safety needs.

Creating Unique Aesthetic Effects with Epoxy

Innovative techniques such as embedding aggregates, creating 3D effects, or incorporating LED lighting can elevate epoxy floors well beyond basic coverage. For example:

- Marble and Concrete Looks: Using color blends and subtle veining, epoxy can mimic natural stone.

- Custom Logos and Graphics: Business branding embedded directly into the floor for a professional appearance.

- Glow-in-the-Dark Epoxy: For entertainment venues or themed spaces, phosphorescent pigments provide unique luminous effects.

These effects require skilled application but significantly enhance the visual impact of your space.

Integrating Logos and Brand Elements in Your Floor Design

Embedding logos, patterns, or branding elements is a popular choice for retail, corporate, and hospitality environments. The process involves:

- Designing the graphic or logo layout in advance.

- Applying stencils or using digital printing techniques.

- Incorporating metallic or colored chips for added depth.

This integration not only enhances aesthetics but also reinforces brand identity and creates a memorable impression for clients and visitors.

Installation Process and Best Practices

Preparing the Surface for Optimal Results

Thorough surface preparation is critical. Steps include:

- Cleaning to remove dust, oil, and existing coatings.

- Grinding or shot blasting to create a profile that enhances epoxy adhesion.

- Repairs of cracks or surface inconsistencies.

- Ensuring moisture levels are within acceptable limits.

Proper preparation minimizes future issues like delamination or surface imperfections.

Step-by-Step Application of Epoxy Resin

The process generally involves:

- Priming the prepared surface.

- Applying a base coat for adhesion and aesthetic base.

- Rolling or troweling the epoxy mixture in uniform layers.

- Adding decorative chips or effects as desired.

- Sealing with a topcoat for protection and finish enhancement.

Time specifics vary depending on product specifications and environmental conditions. Professional expertise ensures the correct mixing ratios, application thickness, and curing times.

Common Mistakes and How to Avoid Them

Typical pitfalls include:

- Applying epoxy over poorly prepared surfaces.

- Inadequate mixing of resin and hardener.

- Applying coats in unsuitable weather conditions—extreme heat or cold can impair curing.

- Rushing the curing process, leading to peel or surface imperfections.

Mitigating these issues requires careful planning, following manufacturer guidelines, and choosing experienced installers.

Maintenance and Longevity of Epoxy Floors

Cleaning and Care Tips for Durability

To preserve the appearance and integrity:

- Regular sweeping or vacuuming removes dirt and grit that can cause abrasion.

- Using mild cleaning solutions and avoiding harsh chemicals prevents surface discoloration or damage.

- Immediate cleanup of spills, especially oils and acids, reduces staining risks.

Repair and Refinishing Options

Over time, minor damages such as chips or scratches can be repaired with compatible patching compounds. In cases of extensive wear, refinishing involves sanding and re-coating, restoring the floor’s original luster and function.

Performance Metrics and Expected Lifespan

Under ideal conditions and proper maintenance, epoxy floors can last between 10 and 20 years. Their performance in resisting chemicals, impacts, and abrasion makes them a preferred choice for demanding environments. Factors affecting lifespan include:

- Quality of the epoxy product used

- Installation techniques

- Frequency and type of traffic

- Environmental exposures

Cost Considerations and How to Choose the Right Provider

Pricing Factors and Budgeting Tips

Costs vary depending on:

- Size of the area

- Complexity of design and customization

- Type of epoxy system selected

- Preparation and site conditions

Investing in high-quality epoxy systems and experienced installers may have higher upfront costs but ensures longevity and performance savings in the long run.

What to Look for in a Flooring Contractor

Key factors include:

- Relevant experience and proven portfolio

- Certifications and adherence to industry standards

- Transparent quotes and detailed project plans

- Positive references and reviews

- Availability for post-installation support and maintenance guidance

Evaluating Quality and Value for Money

Balance cost against durability, aesthetic options, and service quality. Budgeting appropriately and selecting reputable contractors ensures optimal results, maximizing your investment.